In general, if you don’t have a sufficient amount of images to solve a classification problem for high-dimensional data, a vast amount of it is required to prevent overfitting (the learning system fits its learning data so well that it does not generalize to new data). However, Sparse Modeling a data analysis technique can be used to extract essential features to prevent this issue, because it’s applied with few amounts of data and when explainability is required. It aims to understand and isolate the factors that have a meaningful impact on a certain occurrence, so the basic assumption is that most of the features of data are insignificant (or zero), and that insights can be derived from a relatively small amount of essential information. When analyzing image data, this technique is very useful if you’re working with damaged pictures with missing data and noise. For instance, it can be applied for image restoration purposes and super-resolution image processing.

Sparse Modelling for HSI

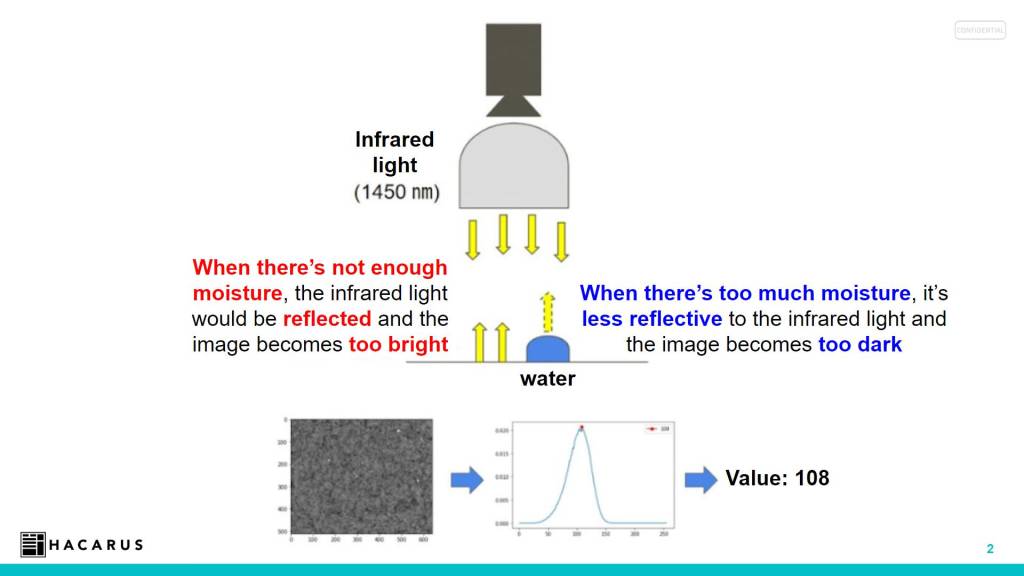

By using NIR cameras that are capable of detecting more than 100 different wavelengths through HSI, Hacarus developed an AI-powered inspection technology system through Sparse Modeling for a Japanese company called DKS, which increased their conventional inspection speed by 600% and through digital transformation. DKS is a company that manufactures a chemical product used in a wide range of applications from lithium-ion batteries to high-grade fish feed. The challenge in this manufacturing process is to identify and adjust the moisture level and its distribution, usually detected from the operators by using their hands and feeling it. But through the near-infrared cameras and analyzing the data through HSI it can be detected whenever the product has too much moisture in it, or if there is not enough. Furthermore, the state and peak value of the moisture level can be graphed and expressed numerically by the AI module. After implementation the AI & HSI system achieved prediction results at the same level as if a veteran operator made the inspections. Before implementing the automation through AI, DKS‘ work time required for one measurement and inspection was about 30 minutes, but in some cases it was reduced to about five minutes, which is about 84%. DKS expects to reduce its inspection labor and training costs by about 50% over the next two or three years.

The Yatsuhasi Experiment

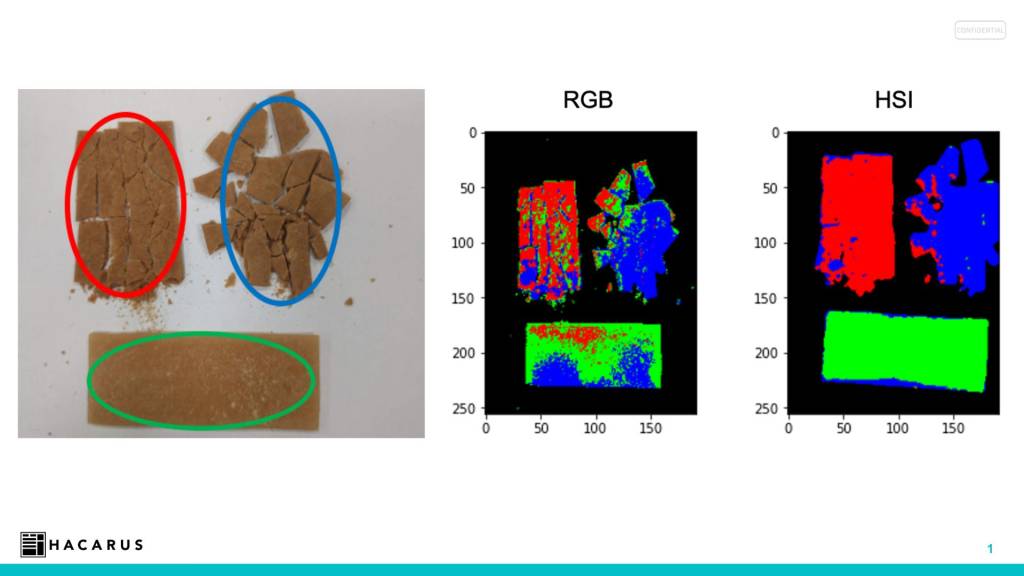

By using Sparse Modeling, Hacarus conducted an experiment to confirm if it was possible to identify the manufacturer of different Yatsuhashi, which is a traditional Japanese confectionery, mainly for souvenir snacks. These hard crackers are made out of rice flour, sugar, and cinnamon. In Figure 1, the top left & right crackers are two Yatsuhashi made from different manufacturers, and the bottom image is from a raw Yatsuhashi before being baked. The objective was to distinguish which Yatsuhashi is which, based on the pixels in each image and comparing the results of both RGB and HSI. The results show that misclassification with RGB is quite common due to the influence of light and other factors, and even the classification of whether a Yatsuhashi was raw or not, was not of high accuracy. On the other hand, the HSI results show that it is capable of classifying all types of Yatsuhashi, proving that Sparse Modeling is an effective way to handle this type of high-dimensional data. n

www.hacarus.com