Bild: Opto Engineering srl

Bild: Opto Engineering srl

Bild: Opto Engineering srl

Bild: Opto Engineering srl

Bild: Opto Engineering srl

Bild: Opto Engineering srl

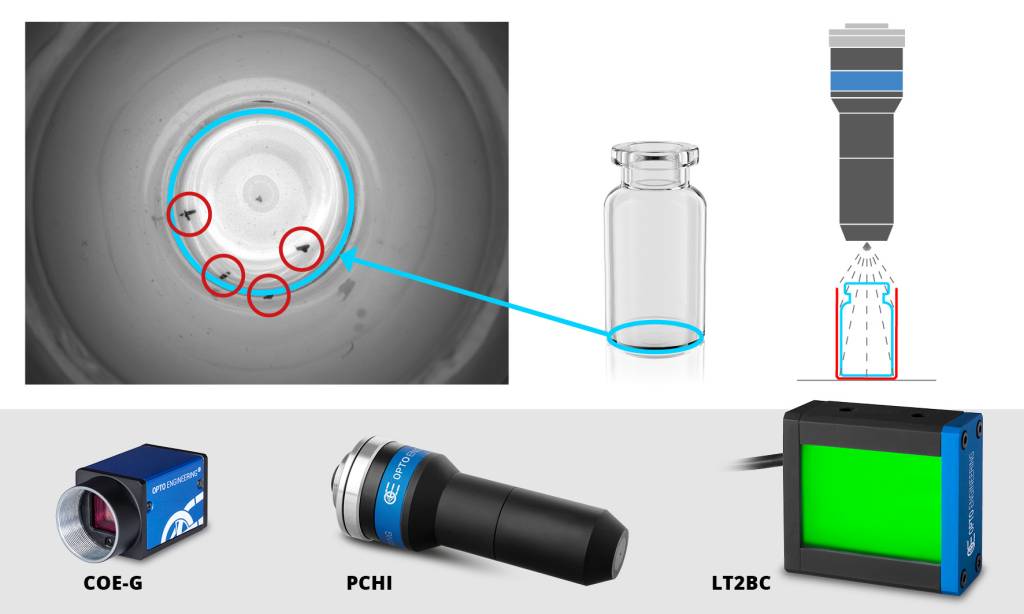

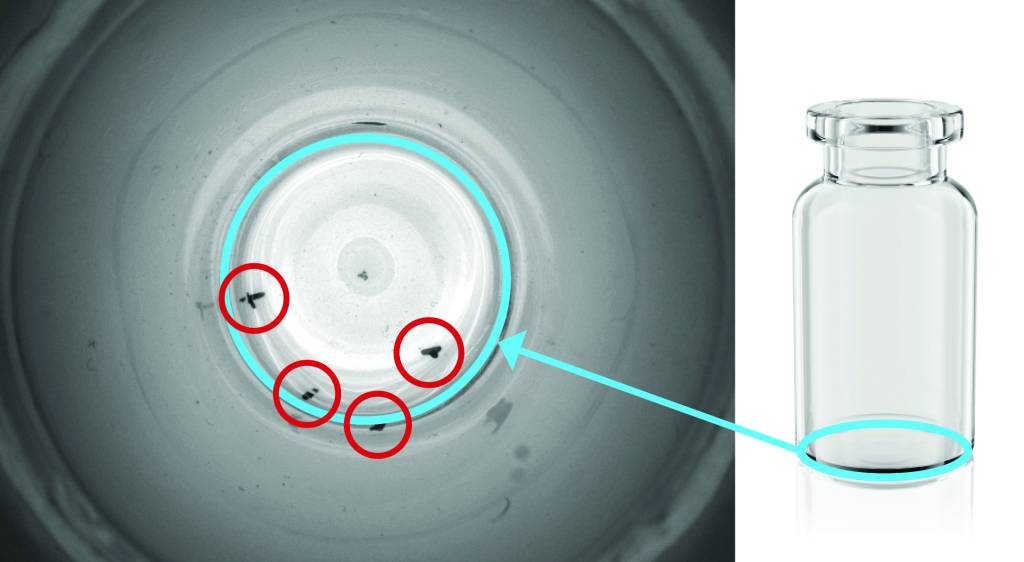

Image 1 | Inspection outcome of bottom impurities on an empty vial with a PCHI lens. – Image: Opto Engineering srl

Image: Opto Engineering srl

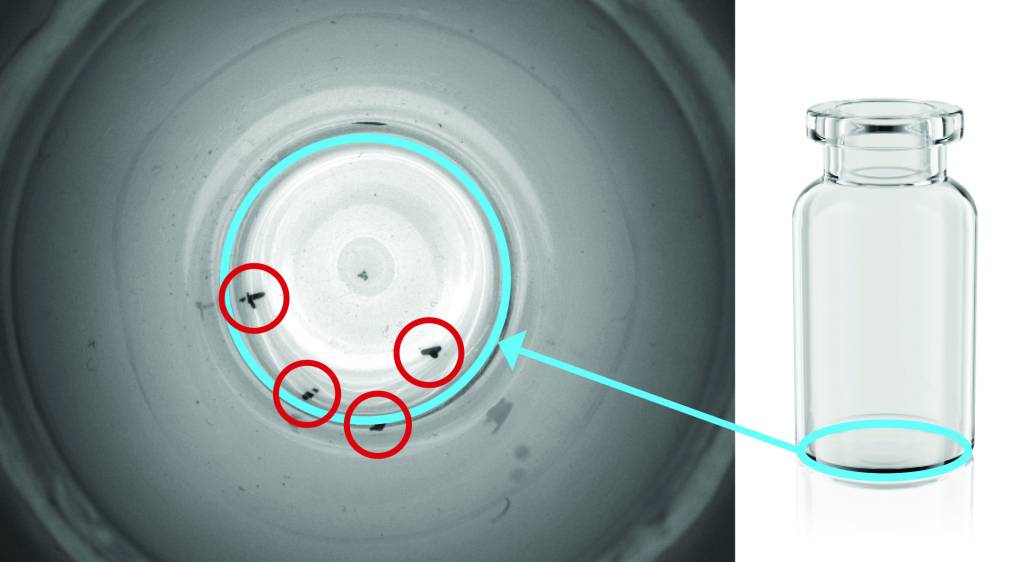

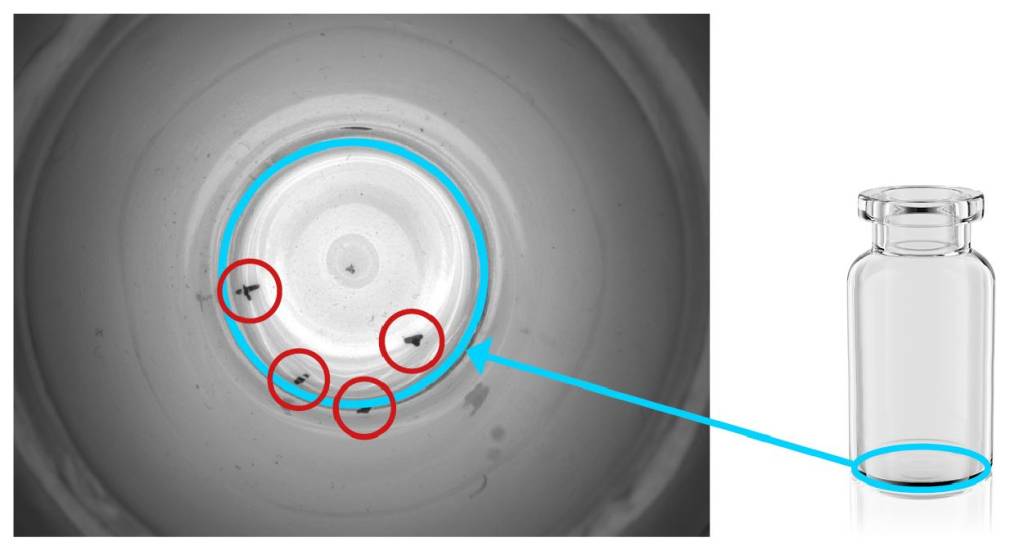

Bild 2 I Inspection outcome of bottom impurities on an empty vial with a PCHI lens. – Image: Opto Engineering srl

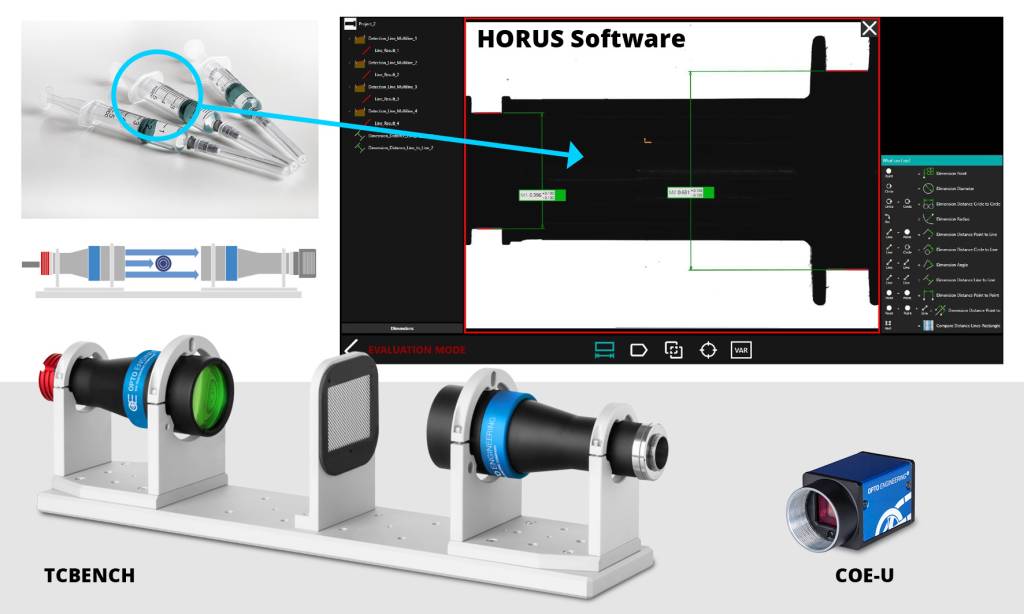

The inspection of pharmaceutical syringes is an extremely important step in the production process. These products must meet the highest quality requirements as well as being affordable. Defects of just 10 to 100m can be detected by imaging, such as contamination and inclusions in the syringe body, faulty prints, or smudges on the needle. Dimensional measurement can be performed on various parts of the product with extreme precision, using telecentric lenses (TC series), collimated illuminators (LTCLHP series) and tailored software (Horus). It is also possible to carry out a complete functional inspection on the entire body of the syringe to ensure that the cylinder, plunger, and fitting are working properly. Users can get a 360° view of syringes using, for example the TCCAGE series lenses, a solution that combines lenses and mirrors. Inspecting thousands of pieces per minute at high speed is not a problem thanks to high-power illuminators and power control drivers such as the LTDV series.

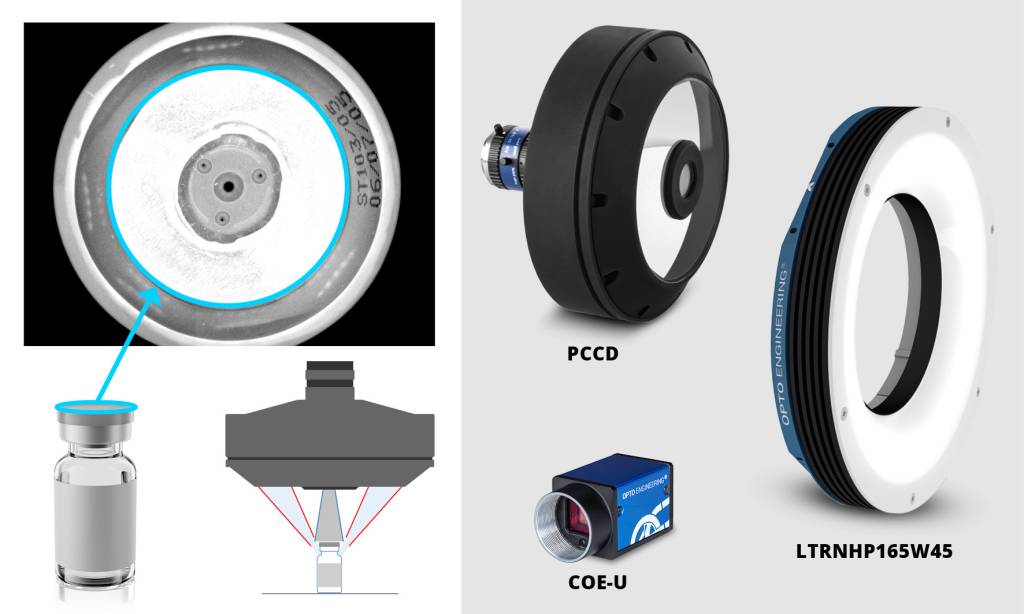

Vials used for pharmaceutical purposes must meet the same strict quality standards. Defects such as cracks, inclusions, and possible contamination (particulate matter, dust) are generally inspected at the beginning of the production process, when the vial is still empty, using, for example, the wide angle of view and high resolution of the PCHI lenses series lenses. Unlike conventional optics or so-called pinhole lenses that can only image flat fields of view, hole inspection optics are specifically designed to image both the bottom of a cavity and its vertical walls. The filled vial liquid level is checked, and possible contaminants are also detected, combining fixed focal lenses (EN5MP series) with high homogeneity flat backlights (LTBP series). Special software environments such as FabImage allow the creation of an image analysis program in a few minutes. Reading the writings (OCR), barcodes, and/or arrays is necessary to ensure that the vial reports the correct information. This application can be solved using 360° view lenses like the PC and PCCD series for external inspection. These objectives, designed and manufactured exclusively by Opto Engineering, enable imaging of objects with a minimum diameter of 7,5mm. With PCCD series lenses, the object sides are imaged by the catadioptric system, while the top side is imaged directly in the center of the detector. On the other hand, the innovative design of PC Series, allows one camera to see the top and lateral surfaces of an object in perfect focus all in one image without using mirrors.

www.opto-e.com