Imagine being able to reduce false alarms by 99% as a caregiver, giving you more time to focus on genuine care. With Kepler Vision Night Nurse, a fall detection system, this is now possible. The AI healthcare software monitors the well-being of individuals. Besides fall prevention and fall detection, it also detects patients‘ lying position, reducing the risk of pressure ulcers.

Kategorie: KI & Deep Learning

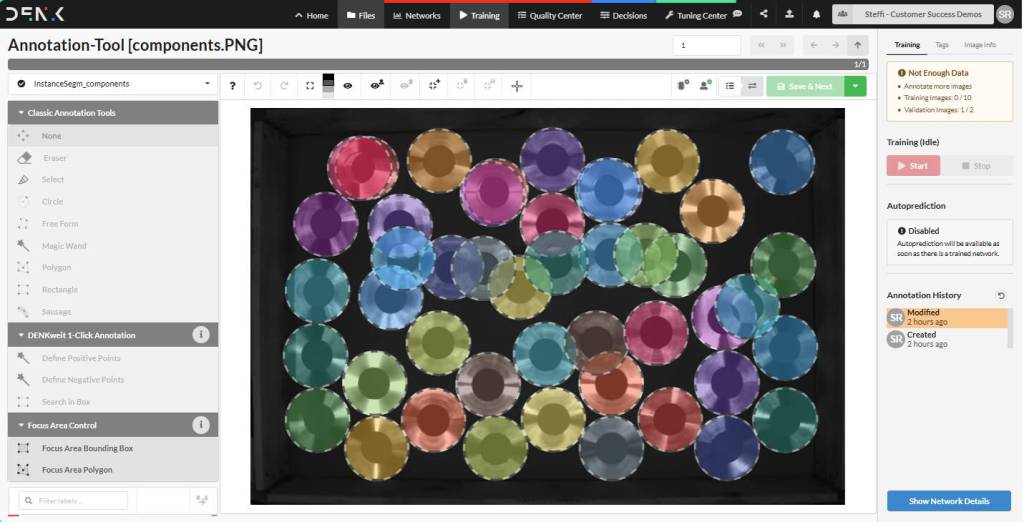

Just Press Play

With the Denk Vision AI Hub of Denkweit anyone without expertise or complex hardware can implement image recognition/evaluation in just a few clicks from 15 images. By using the new technologies, customers receive high-performance and reliable solutions with a simple click on ´Play´. The technology is used in all markets and areas where processes need to be automated and optimized.

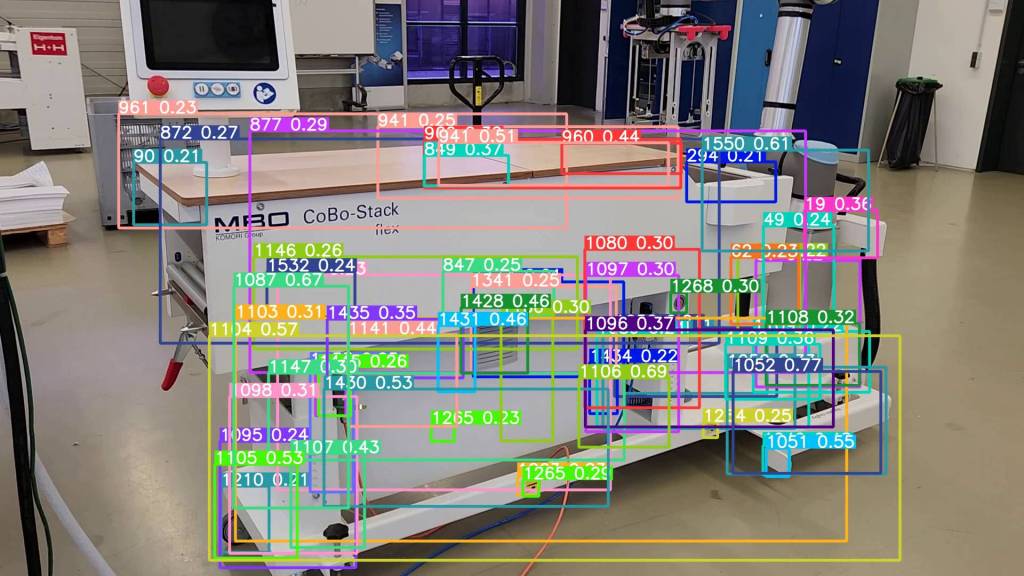

1-Click Spare Part Identification

Imagine taking a photo of a machine with your smartphone and seeing at a glance which spare parts are installed in which place, and being able to order them directly and replace them accordingly. No manual search. This article delves into the technical aspects of synthavo’s AI-based technology, highlighting how it transforms the process of spare parts identification and enhances efficiency in the manufacturing sector.

Real-world Ground Truth for AI

Developing reliable training data for in-cabin sensing and VR is challenging. Action and gesture recognition are hard to model, making the process expensive and time-consuming. At the same time, institutions such as Euro NCAP attach significant importance to validation with real people and in real-world conditions. rabbitAI has mastered these challenges with a real-world ground truth capturing solution.

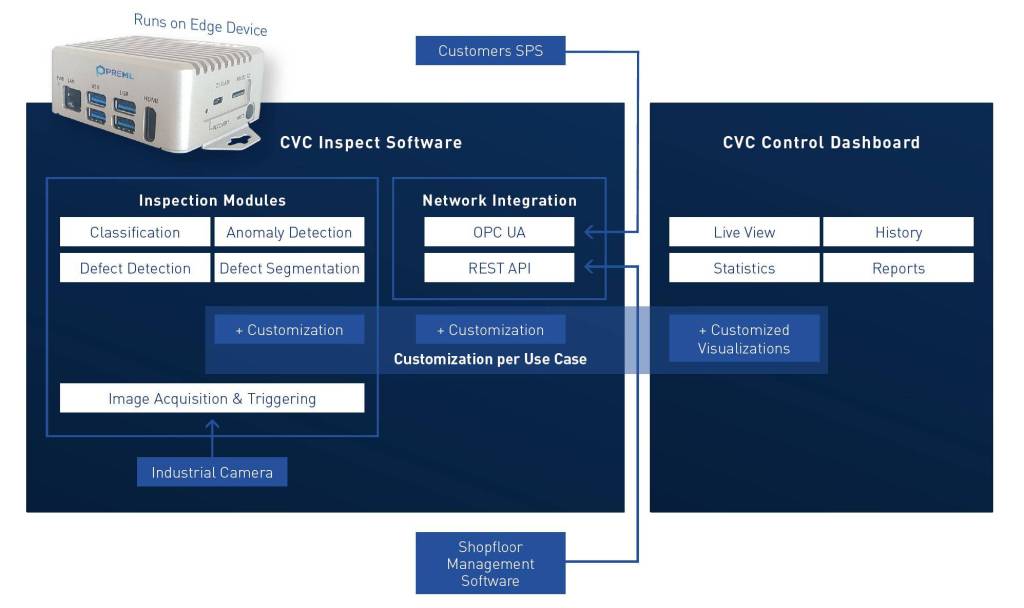

Customized AI Vision

In the past year alone, several toolkits and platforms dedicated to AI in visual inspection have emerged. However, these tools are mostly designed to make AI accessible to non-expert users, by restricting parameters and features. This works well for simple use cases. Yet, many manufacturers still want an easy-to-use turnkey solution for their complex products, including external service and consulting, as they are used to. Recognizing the evolving needs in visual quality inspection, PreML developed CVC Inspect, a Python-based framework designed to automate visual inspection tasks fast and efficiently.

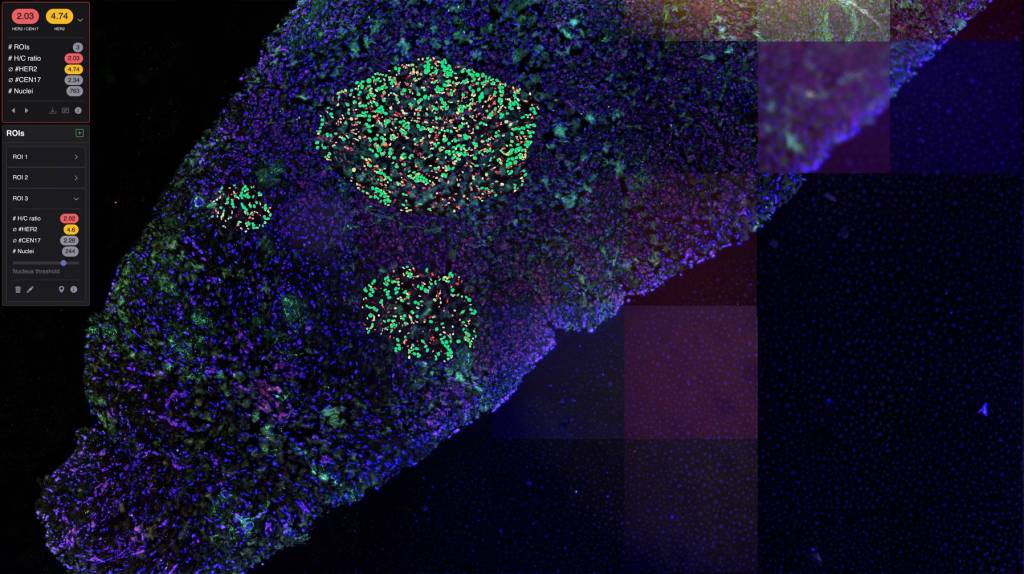

AI to fight cancer

Cancer diagnostics by pathologists is time-consuming and labor-intensive. The global increase in cancer cases and a decline in the number of pathologists have created a pressing need for more efficient and accurate diagnostic methods. AI-assisted diagnostic tools offer the possibility of automating and speeding up tissue analysis. Katana Labs focuses on AI-driven software solutions for precise cancer tissue analysis.

Weld Seam Inspection

Iuna AI Systems specializes in the development of deep learning-based image processing software and camera systems. Since its founding in 2020 the company has aimed to automate quality assurance in industrial manufacturing using AI technology. In this article, the benefits and applications of the AI Weld Seam Vision System for quality assurance of MIG/MAG weld seams and other possibilities for automation through AI-based computer vision are highlighted.

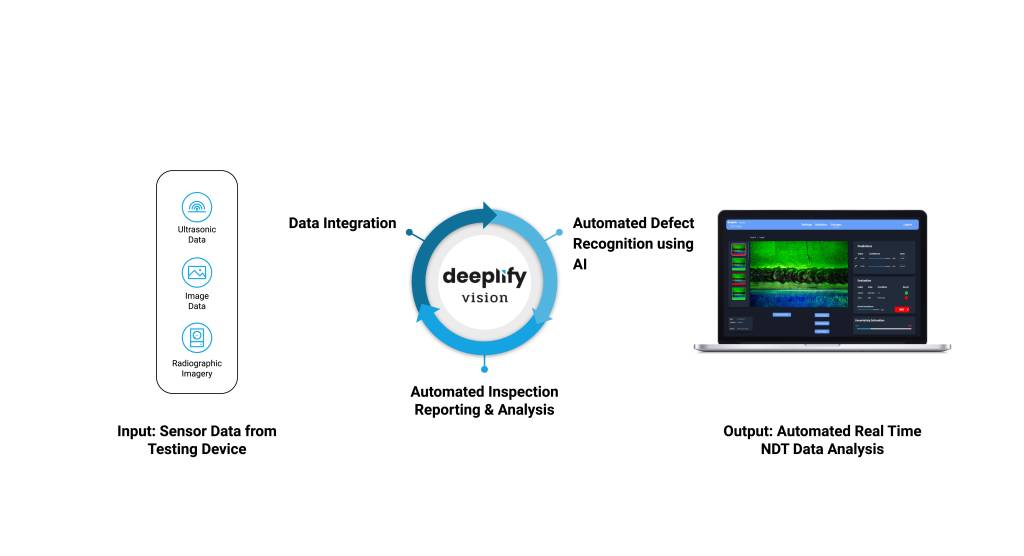

Bringing AI into NDT

Deeplify’s AI-based inspection platform enables manufacturing and testing companies to create and deploy customized AI-based inspection systems using their own sensor data. The company currently focus on X-ray, Ultrasonic, and Magnetic Particle inspection, and will incorporate additional NDT methods over time.

Continual Learning

MVTec präsentiert im Jahr 2024 mit Uncertainty Estimation und Continual Learning zwei neue Deep Learning Features. Das erste sorgt für die verlässliche Erkennung von Veränderungen, während das zweite Feature den Aufwand für das Nachtraining von DL-Algorithmen deutlich verringert.

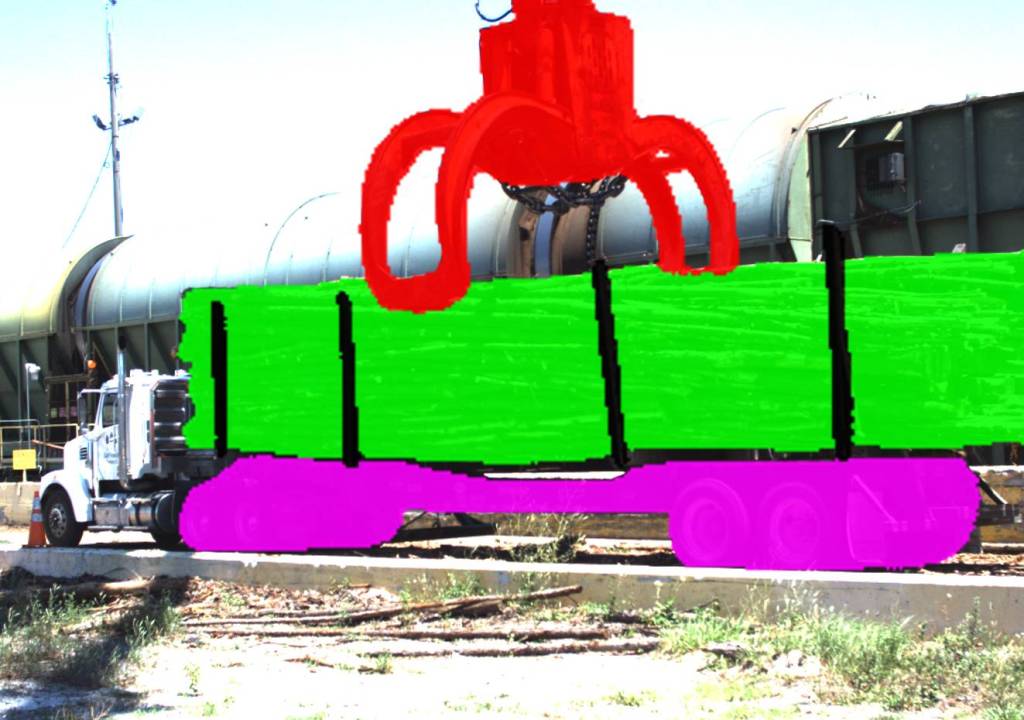

Autonome Steuerung von Kranen mit KI-Vision

Im Holzverladebereich von Zellstoffwerken werden Krane noch weitestgehend manuell gesteuert. In diese Automatisierungslücke stößt die Kran-AI (KAI) von Psiori, welche die autonome Steuerung von Kranen mittels KI-Vision ermöglicht.