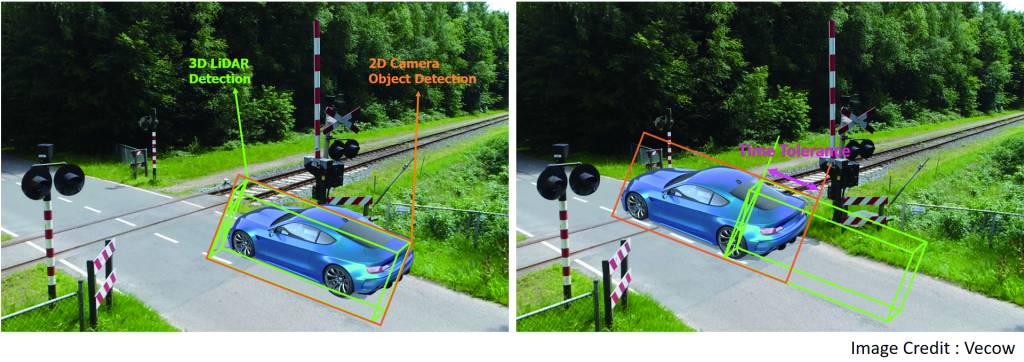

@MZ_Grundschrift:It’s important to note that the data and actions as a result of that data coming out of the robot is only as good as the data going in, and that has a lot to do with not only the sensors themselves, but how (and when) the data from those sensors is received. One phenomenon that could plague outdoor mobile robots is data misalignment, which refers to a situation where the information or data gathered by the robot’s sensors, such as cameras, LiDAR, or GPS, does not accurately correspond to the robot’s actual physical position or the environment that it is navigating. This misalignment can occur for various reasons, including proper sensor calibration, changes to the environment, mechanical wear and tear across all the components, and the inevitable software bugs. The bottom line is that if you don’t have an accurate time synchronization when the robot starts out, everything you do from that point forward has the potential to be inaccurate. And history has shown that there is no such thing as perfect (bug-free) code. Those bugs or errors in the robot’s control and perception software can lead to data misalignment, causing the robot to make incorrect decisions or navigate inaccurately. @MZ_Grundschrift: @MZ_Grundschrift:Synchronization Through Time @MZ_Grundschrift:Winding and Stamping @MZ_Grundschrift:Time winding is a key component of data synchronization. The concept refers to aligning the GNSS (Global Navigation Satellite System) with the internal clock on the robot. GNSS refers to a constellation of satellites that transmits timing data to the receivers within the robots. Time winding also involves continuous PPS (pulse per second) triggering of all node. The result should be a guarantee that all sensors are working from the same baseline measurement. Then comes time stamping, another data-synchronization component where the information is physically written to the sensor. This measurement represents the exact time with nanosecond accuracy. Even if the robot (or vehicle) temporarily loses contact with the satellite, the stamping is still capable to provide the time information to all sensors. Time stamping works hand-in-hand with the time-keeping function, which lets the robot keep time for itself until the robot can reengage with the satellite. Time stamping pushes the time protocol to all nodes and ensures that all sensors are synced, and it typically supports a host of frequencies. The data for the timekeeping function is generated using an FPGA running at a very high speed, which is what permits the nanosecond accuracy. The time-keeping feature manages the precise local time data while employing anti-jamming techniques. @MZ_Grundschrift: @MZ_Grundschrift:Daisy Chaining @MZ_Grundschrift:Then there is daisy chaining, a function that’s (mostly) specific to Vecow, a provider of embedded computers for outdoor mobile robot applications. Primarily a software function for automated time synchronization, daisy chaining involves expanding the synchronization channels for sensor nodes and controllers. There is typically one master that keeps the time, which is then transmitted to the various slaves within the system. Daisy chaining can be done for a sensor-node-to-sensor-node sync or a controller-to-controller sync. Another method that’s been used is real-time kinematic (RTK) positioning, which is defined as a high-precision satellite navigation technique that can determine the precise position of a receiver. Using this sophisticated statistical method to adjust the phase of these signals can provide an accuracy down to just centimeter-level in many cases @MZ_Grundschrift: @MZ_Grundschrift:Time Synchronization Solution @MZ_Grundschrift:One embedded computing platform that can handle the time-synchronization process is Vecow’s Time Sync Box VTS-1000. The system integrates GNSS and high-precision inertial measurement unit (IMU) components, providing a multi-synchronization function, thereby allowing external sensors to take care of all the sensor synchronization. In the case of the VTS-1000, the three key technologies are covered: time winding, time stamping, and time keeping. The system also provides the ROS topics that are needed for robot users to subscribe to the time information, IMU raw data, or additional camera data. Out in the field, it combines with the company’s ECX-3000 high-performance platform, which is powered by 13th Gen Intel Core i9-13900TE. Running at 5GHz and the ability to house up to 24 cores, the platform is well suited for AI applications and those that require time synchronization. The ECX-3000 integrates the software and algorithms needed for outdoor mobile robot applications. Other features include eight independent 2.5G LAN connections with four IEEE 802.3at PoE+ ports, four front-access M.2 SSD trays, and six USB 3.2 Gen 2 ports. The combined solution provides a multi-channel time-of-day (ToD) output for external multi-sensors, a PTP/gPTP Gigabit Ethernet port, and one Gigabit Ethernet port for ROS 2/DDS pub/sub output. It also includes a dual GNSS antenna for robot heading and integrates an Xsens MTi-670 high-precision nine-axis IMU. For easy configuration of synchronization protocols and frequency based on sensor requirements, Vecow offers a Python tool. n @MZ_Grundschrift:Hall 8 | Booth C15