Despite significant advancements in inspection equipment, data analysis for safety-critical inspections in non-destructive testing (NDT) still largely relies on manual interpretation by certified inspectors. The industry faces a shortage of skilled labor due to the retirement of seasoned NDT inspectors, creating an urgent need for enhanced automation in data analysis. Recent developments in AI and machine learning technologies have demonstrated the potential to outperform humans. However, for these AI-based inspection solutions to be effective, they must be specifically tailored to each application and integrated into functional inspection software.

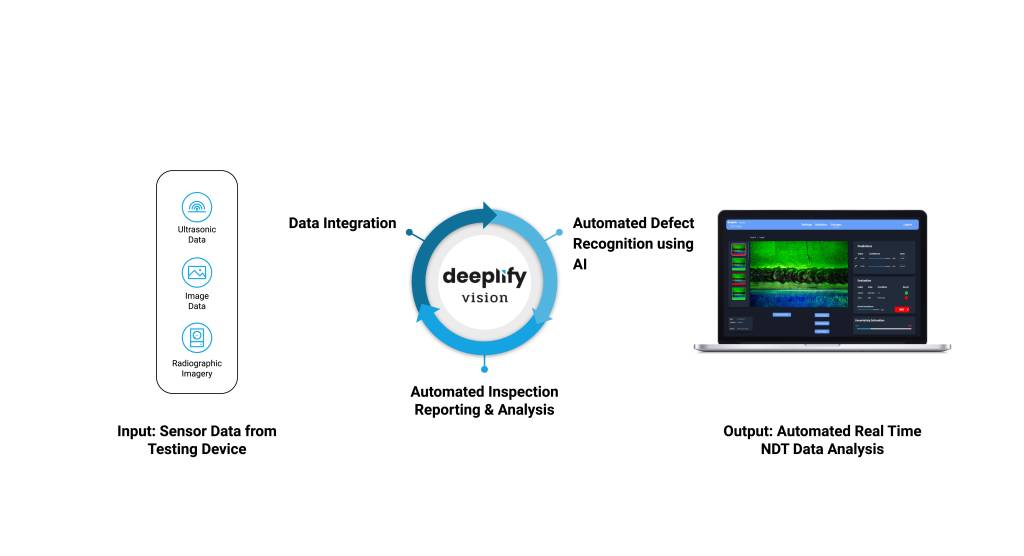

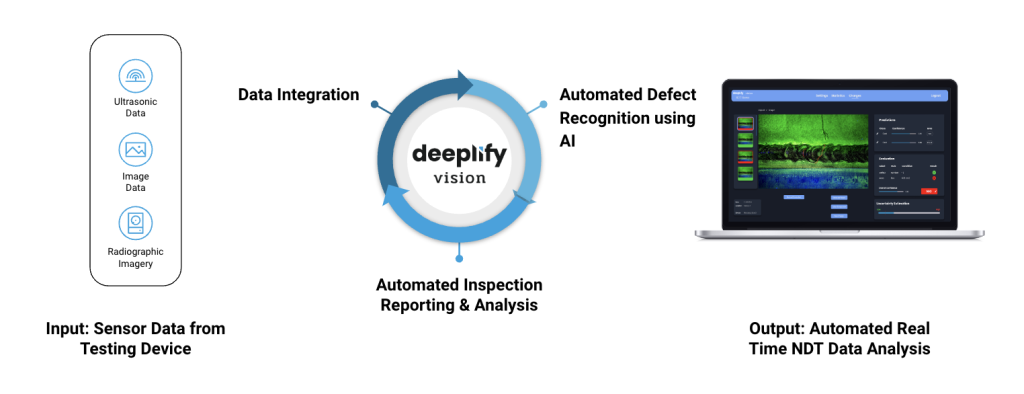

Deeplify addresses this challenge by developing an AI-based inspection platform. The platform enables manufacturing and testing companies to create and deploy customized AI-based inspection systems using their own sensor data. This allows their customers to improve defect detection, reduce testing costs, and increase operational efficiency. The company currently focus on X-ray, Ultrasonic, and Magnetic Particle inspection, and will incorporate additional NDT methods over time. The end-to-end platform approach automates NDT data analysis, covering the entire inspection workflow and AI development lifecycle, enabling teams without engineering or AI backgrounds to leverage the latest AI techniques for their NDT inspections.

AI Labelling Tool for Every Data

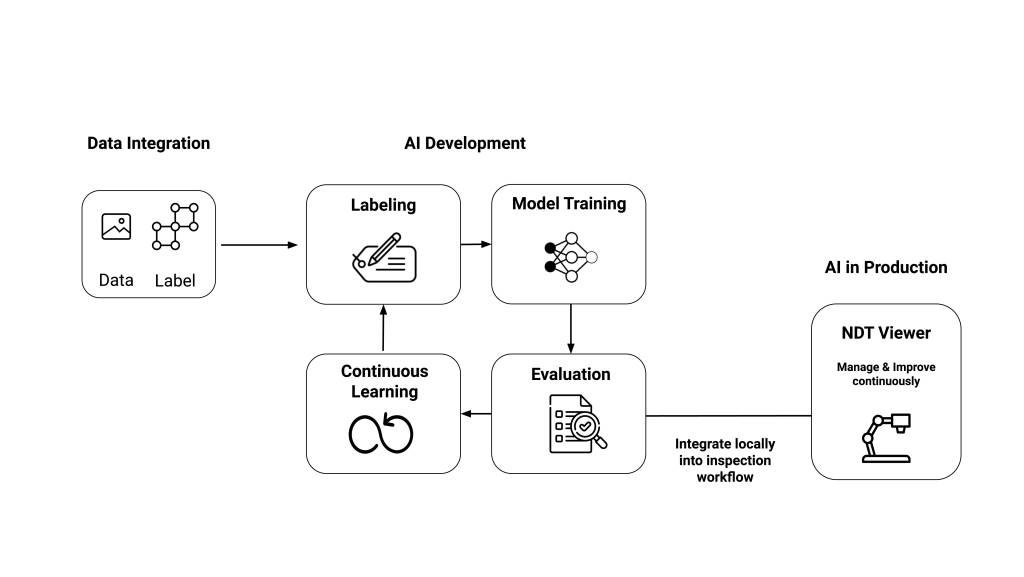

The platform features an intuitive labelling tool for efficient data annotation, adhering to industry norms and standards. Users can train AI models with their datasets or fine-tune the application-specific foundation models. The platform supports annotation and training for RGB image data, X-ray data, and ultrasonic data, utilizing state-of-the-art neural networks (CNNs and transformers) optimized for each use case. The foundation model approach allows customers to achieve high model performance without the need to collect and label massive datasets. All data can be stored and archived in a single repository for easy access and management. The hardware-agnostic platform supports all major data interfaces, consolidating data from various NDT inspection devices (Diconde, HDF5, JSON, etc.). The interfaces transfer data to a dedicated PACS server for audit-proof archiving, ensuring long-term storage throughout the asset’s lifecycle. Trained AI models are tested on independent validation datasets. The platform offers a range of metrics to monitor and optimize for (e.g. Probability-of-Detection POD, recall, precision, accuracy, pseudo detection, and more).

Combining AI with Human Expertise

Once the metrics meet the required performance, the model can be deployed with a single click to the deeplify Vision NDT Viewer. The viewer visualizes results and integrates into existing inspection workflows, capable of operating fully automatically or in parallel as an assistant tool for inspectors. NDT inspectors can apply customized decision rules, such as critical indication size or number of indications, to automate the decision-making process or retain the final decision authority. Inspectors can correct defect predictions, with the data uploaded to the deeplify Vision platform for model retraining, enabling rapid model improvements and self-maintenance of AI-based solutions. The interpretative skills of qualified NDT inspectors remain crucial, especially in complex situations. Therefore, the NDT Viewer is optimized for efficient human-machine interaction, combining AI with human expertise to ensure comprehensive and precise analysis, enhancing the system’s effectiveness and accuracy over time.

NDT Applications

One of many applications was magnetic particle crack detection, where deeplify partnered with Karl Deutsch, an OEM manufacturer of testing equipment, to offer automated AI-based detection of MT indications. Further applications include automated X-ray inspection systems for casting parts in the automotive and aerospace industries, demonstrating theability to significantly reduce the time to value by deploying automated inspection systems within weeks. Also assistant systems for weld inspections and wall thickness measurement were developed, supporting the analysis of X-ray images of pipelines. Furthermore, the company is currently piloting an ultrasonic inspection system for railroad wheels that utilizes phased array ultrasonic testing data. These use cases showcase the software’s versatility and efficiency, providing industry-specific solutions that deliver accurate results, flexible deployment options, and scalability.