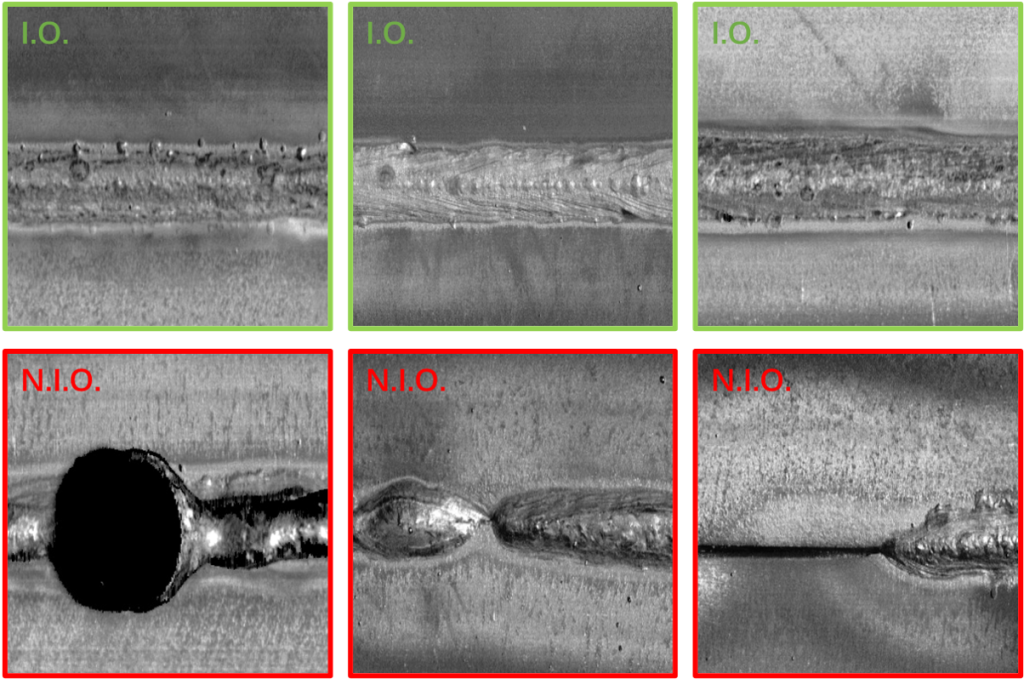

Quality assurance of weld seams is a critical process in manufacturing, especially for safety-relevant components such as those in the automotive industry. The Iuna AI Weld Seam Vision System offers an innovative solution for inspecting MIG/MAG weld seams in both manual and robot-assisted welding. In robot-assisted welding, the camera is mounted directly on the robot, while in manual welding, multiple cameras are integrated into the production line. By using deep learning-based object detection, segmentation, and classification models, the system can recognize the various production steps of the worker in real time and always check the last welded seam. This enables complete automation of visual inspection even in manual welding. This is particularly advantageous in the production of small-series vehicles, where a lot of manual welding is still performed.

Inspecting Individual Weld Seams

The Iuna AI Weld Seam Vision System is scalable and can be used for inspecting individual weld seams to a complete vehicle. Data processing is performed on a local AI inference server, so no online or cloud connection is required. This guarantees maximum process security and protects sensitive data. Another advantage is the high reliability compared to human visual inspection. This is particularly important for safety-relevant weld seams, such as those found in vehicles or aircraft. Additionally, the system is more cost-effective than manual inspection. Iuna AI Systems develops both the hardware and software, as well as the AI models in-house, to offer customers maximum quality and reliability. Established OEMs already trust the AI Weld Seam Vision System to optimize their production processes and ensure quality.

Further Applications

In addition to the Weld Seam Vision System, Iuna AI offers other vision systems that can automate various processes of industrial manufacturing. The Iuna AI Autoscanner is specifically designed for inspecting vehicle surfaces. It detects and classifies surface defects in real time, helping to ensure a flawless vehicle surface. The AI Scanner, on the other hand, enables the automation of various applications, such as completeness or surface inspection. These versatile applications make the new vision systems an essential tool in modern industrial production.

Summary

Iuna AI Systems specializes in technological development in the field of quality assurance through AI-based image processing. With the Weld Seam Vision System, Iuna AI offers a powerful solution for inspecting MIG/MAG weld seams that can be used in both manual and robot-assisted welding. By using advanced deep learning models and powerful hardware, the company ensures reliable and cost-effective inspection that meets the high demands of the industry. The wide range of automation options offered by the new vision systems underlines the broad range of applications and the added value of this technology for industrial production.