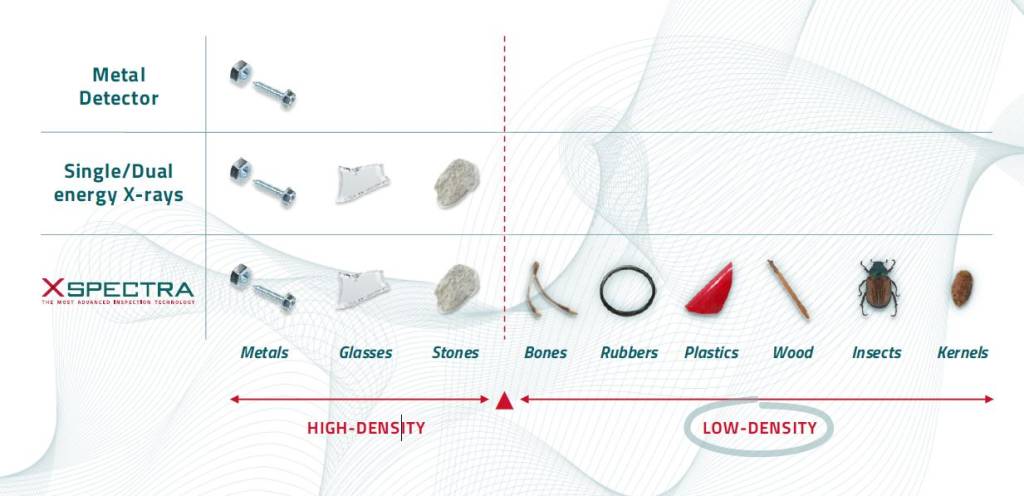

Nowadays, ensuring the food safety and quality of the food we consume is an increasingly complex challenge that requires new technologies and instrumentation. With intensive and fast production it is more and more likely that food will come into contact with materials and foreign bodies with which it should not, that if not detected in time end up contaminating products and spreading to the packaging and consequently to the consumer’s plate. To prevent these problems from arising, food companies already use inspection systems such as metal detectors or single or dual energy x-rays. However, these are not always able to intercept all types of contamination because they stop at metal and ferrous or very dense foreign bodies while failing to detect other lighter foreign bodies such as plastics, bones and cartilage, organic residues, wood and rubber or glass fragments.

Deep Hyperspectral Technology

To solve this problem, Xnext has developed a new technology based on Deep Hyperspectral X-ray analysis in conjunction with a Deep Learning software. XSpectra’s proprietary technology uses an X-ray source, but unlike traditional single- or dual-energy X-ray inspection systems, it performs hyperspectral X-ray analysis in milliseconds, exploiting up to 1024 energy levels of X-rays while competitors use a maximum of two, resulting in the highest accuracy and repeatability in the detection of foreign bodies, which are impossible to detect by conventional systems, regardless of shape, size and position in the package. The system can ensure this analysis thanks to a higher spectral resolution.

The spectral resolution refers to the number of detected bands and their width: the higher the number of bands, the greater the ability to identify imaged objects based on their characteristics. The number of bands detected by the sensor differentiates hyperspectral analysis from the more commonly used multispectral analysis. With the latter, images are acquired in a limited number of distinct, broad and usually non-contiguous bands. Hyperspectral sensors, on the other hand, are able to detect numerous very narrow and closely spaced wavelength intervals, to realise the analysis of the entire photon absorption spectrum. A single hyperspectral image can be represented as a cube of data in which spatial information is collected in the X-Y plane and spectral information is represented along the Z axis. The hyperspectral X-ray analysis performed by XSpectra allows a more complete control of the photon absorption spectrum of the analysed materials and much more data on the composition of the product, enabling more precise and unprecedented inspection and identification of foreign bodies and manufacturing defects. The system is performing at low x-ray energies (down to 5keV) to detect low-density foreign bodies, whereas conventional x-ray based systems start from 25keV up.

Bild: Xnext S.p.A.

Image 3 | The advantage of XSpectra over conventional inspection systems. – Image: Xnext S.p.A.

AI Integration

The enormous potential for XSpectra analysis is amplified by the presence of a Deep Learning software that, thanks to neural networks trained on a large set of products, is able to self-learn product variability by working in parallel with image acquisition. The software improves its performance over time based on data acquired inline during operation. As it analyses data from the absorption spectra of the inspected product, it learns to recognise the product and distinguish between compliant and non-compliant products, increasingly reducing the rate of false rejects and false positives in the direction of a zero-defect food production process. The inspection systems are always connected to the network and can be constantly monitored and analysed remotely, offering the possibility of immediate remedial action and, above all, software updates. XSpectra can also interface with different areas of the production plant such as quality control, process management, operations and analysis to enable intelligent management of each process step, transforming the production line into a Smart Factory.

www.x-next.com