To some extent, 3D inspection implementation is complex because of a uniform scanning: typically, 3D inspection sensors cannot apply different scanning parameters to different regions inside the field-of-view. For example, most existing scanning profilometers and some structure light implementations scan in only a single direction. Single-direction scanning results in non-optimal angles of illumination – particularly when an edge feature is parallel to the illumination – and has the potential for 3D ‚drop out‘ when the angle of the illumination source is obscured from the camera(s). Another constraint is that virtually all existing 3D solutions produce an image with a fixed scan density. This can result in over-sampling of parts of the image to achieve resolution necessary for local features, or under-sampling of features that require higher density.

Feature-based 3D Camera and Autonomous Software

Saccade-MD from Saccade Vision targets to solve these complexities by fully flexible MEMS-based scanning laser. This approach enables selective sub-pixel resolution in 3D. Moreover, use of MEMS-based scanning enables precise scanning of non-moving parts, so imaging quality is not affected by vibrations and motion imprecision. Flexible software allows regional scanning optimization to get best scanning results based on the digital model analysis of the scanned part. Few examples below demonstrate the importance of regional scanning optimization for easy and robust 3D inspection solution:

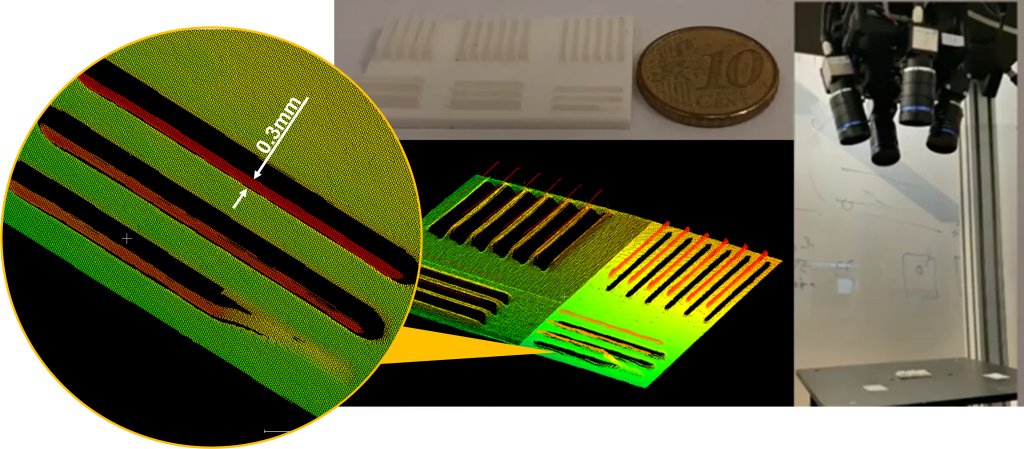

Example 1: Scanning of different regions with different resolution. This 3D-printed part has tiny walls (0.3mm) and to achieve the best quality, these walls were scanned in optimal direction and with optimal parameters. This way sub-pixel resolution in 3D of www.saccadevision.com

www.euclidlabs.it