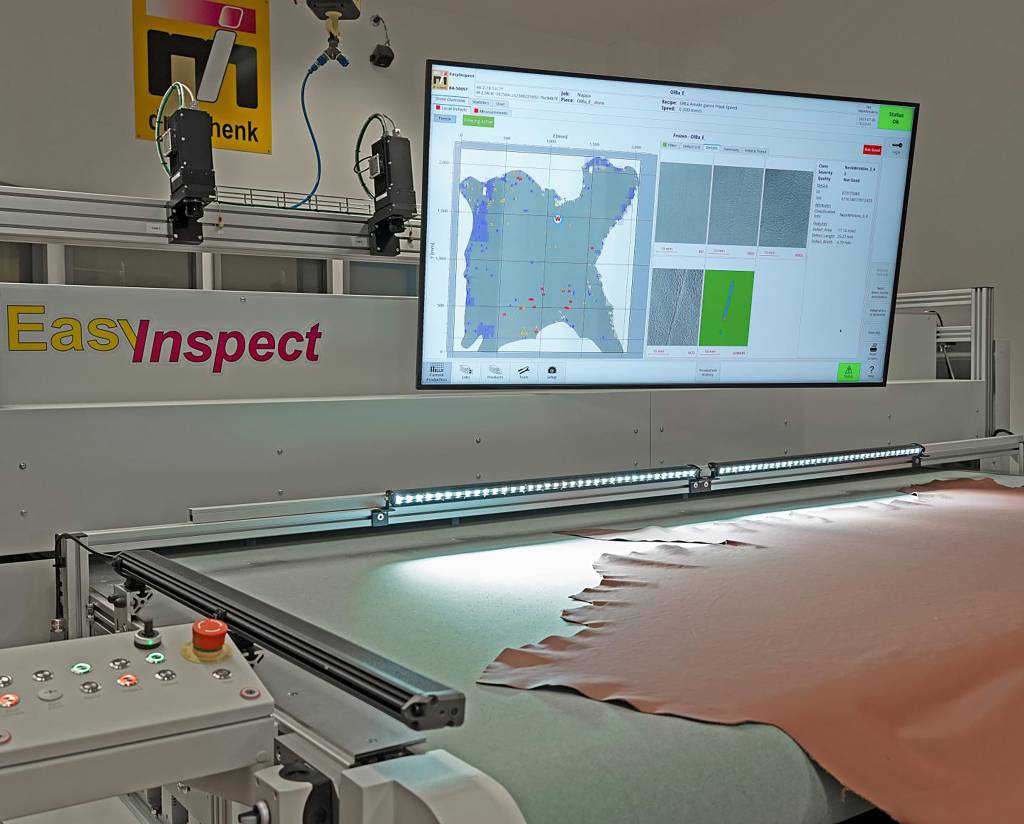

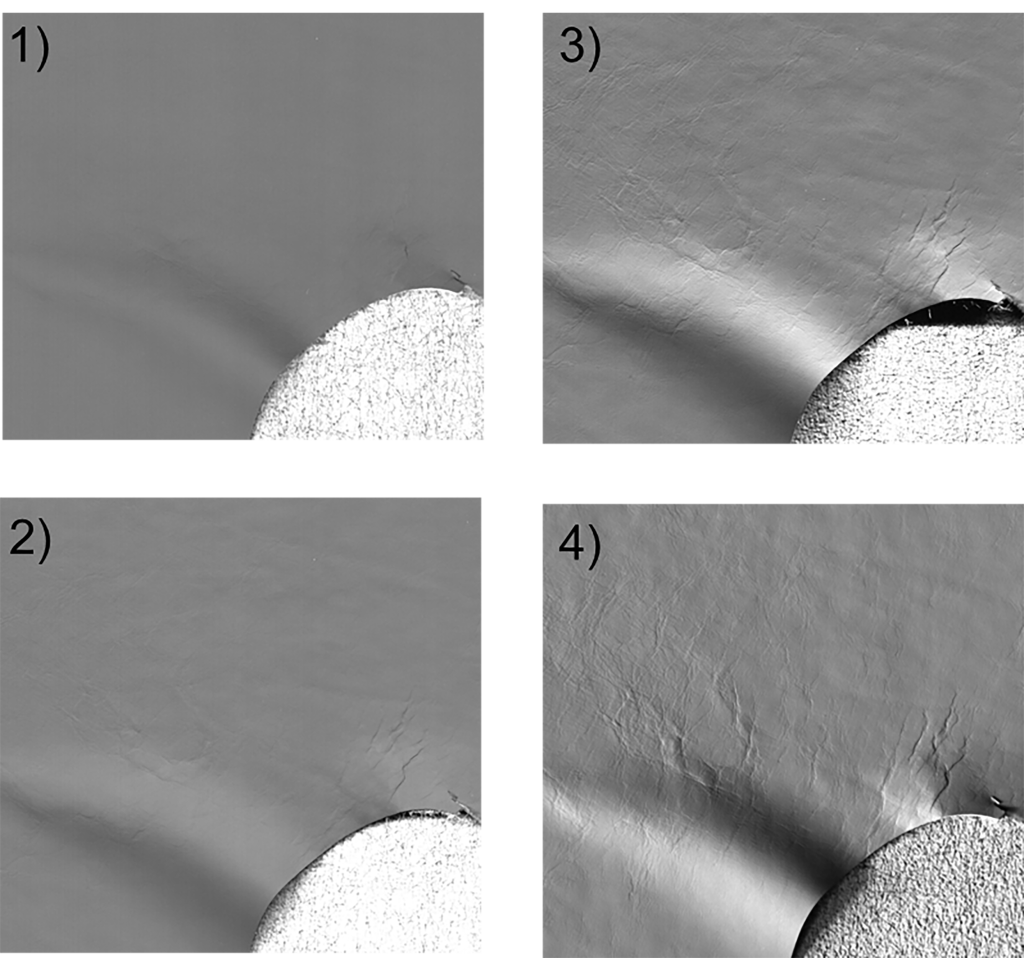

Proprietary Dr. Schenk high-speed smart line scan cameras are combined with dedicated illumination units creating different optical configurations. This makes it possible to highlight all characteristics relevant for detection and qualification of natural flaws in cowhides, which – given their endless variety and shapes – was challenging in the past. A single row of cameras acquires all images with Dr. Schenk’s Multiple Image Defect Analysis (MIDA) technology. At the same time they are analyzing using sophisticated AI models. The first illumination unit enhances differences in color and gloss; the second illumination unit is more sensitive to the structure of the hide’s surface; the third illumination unit makes even more structural details in the hide visible; it also allows analysis of features such as roughness and depth. This third illumination unit is aligned perpendicularly to the transport direction of the hide (CD), offering maximum sensitivity for detection of scars, wrinkles and folds oriented across the hide. When these three-dimensional, mostly elongated, natural flaws are aligned in transport direction (MD), the CD-configuration does not deliver optimum results. For this common scenario the Dr. Schenk oblique illumination is used and has been proven to make all natural flaws visible for further processing.

Image analysis with AI and Deep Learning

This configuration is the foundation for clear identification of all marks in at least one of the four images it gathers. These images are then analyzed using an AI-model. The significant images also enable leather experts to judge the results – crucial in gaining customers‘ confidence during introduction of new technology, as well as for collection of more training data to customize the results according to their demands and experience.

Using all four images, the deep learning model segments and classifies all natural flaws and irregularities on the hides. With a particular focus on inspection of genuine leather, the software department at Dr. Schenk tested various approaches to find a robust and user-friendly evaluation method. The model was trained on data from thousands of hides to offer users of the system a very good starting point. The variety of industries, ranging from automotive to leather goods such as shoes or handbags, meant that many different quality specifications had to be met. Thanks to the proprietary software and experience from these various industries, the user can now easily perform any necessary changes.

Transportation of Hides and Detection Conditions

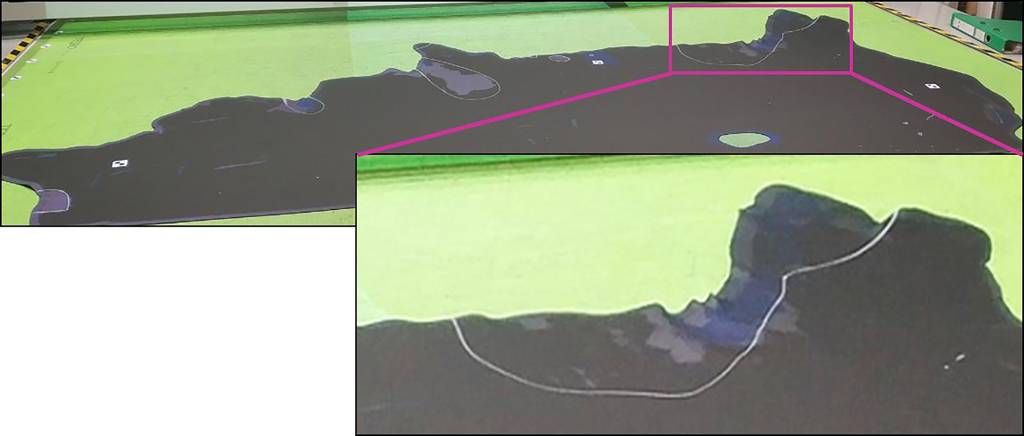

Besides the challenging optical aspects, handling of the hides is a hurdle in achieving outstanding inspection results at reasonable throughput. To make things even more challenging, certain defects such as ‚Butcher Cuts‘ (thin areas in the hide), can be critical regarding quality grading but are not visible on the hide’s surface. To avoid time-consuming inspection of the hide’s back side, the Dr. Schenk solution uses strong vacuum beneath the scanline of the cameras so a butcher cut mark creates a clearly visible dent in the hide’s the top side. Defects, which are only visible by stretching a hide, can be detected in this manner. Furthermore, a light vacuum supports placement of the hides on the conveyor and ensures optimal inspection conditions with minimal wrinkles or folds.

Summary

The advantages of reliable, objective and accurate defect detection and marking before cutting the finished leather are numerous. All inspection results are stored in a database of the inspection system and the automatically created DXF-file ensures seamless integration into existing upstream systems, for example automatic nesting of cut parts. The inspection system performs inspection automatically (without human interaction) at a rate of more than 80 hides per hour.