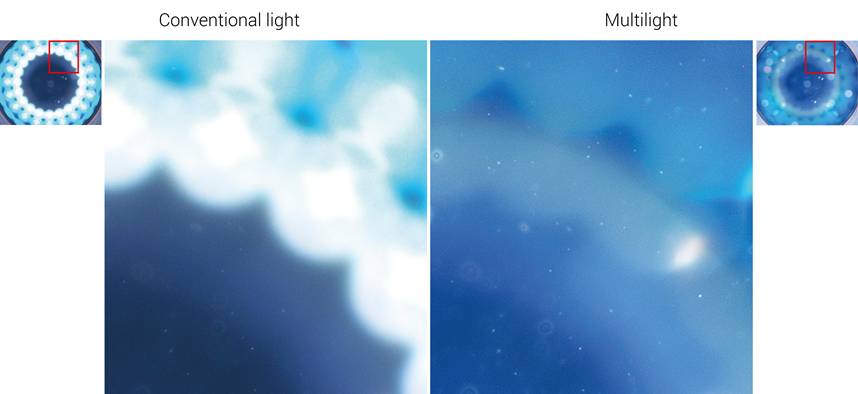

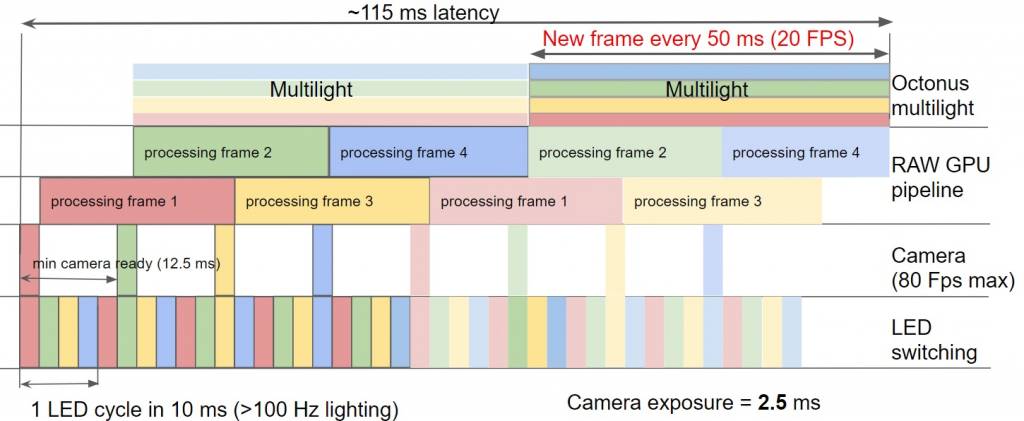

For human and machine vision it is very important to maximize the contrast of inspected features of an objects and remove areas obstructing the inspection, like reflection, glare and shadows. A standard solution for this problem is a careful adjustment of the lighting setup for the inspected scene. A new multi-light technology can empower this solution and in some cases transcend it, by mixing several images of an object with varying lighting environment. On image 1 you see how multi-light technology works on a diode with a lense. A multi-light algorithm takes four images with glare from top light sections and gives the resulting image where specular highlights are removed and enhanced the contrast of the details. One of the most challenging cases for inspection are objects with curved or polished surfaces giving specular reflections and transparent objects. Typical lighting arrangements result in specular reflections at all sample orientations. Multi-light reveals a fine surface structure and internal details. For transparent objects standard lighting create reflections and refractions which obscure internal features. The new technology reveals internal details. On image 2 you can see the comparison of the images of an iPhone XS internal camera lens (second lense under the cover) under conventional light and obtained by multi-light technology. The dust and defects of the lens are visible better on multi-light image.

System build-up

Basically, a multi-light hardware consists of four elements:

- high-speed industrial camera giving RAW16 output (with required for the task optics)

- multi-light illumination consisting from several lighting sections that can be switched on and off independently

- multi-light controller that synchronizes a digital camera with illumination

- PC with GPU for real-time image processing of captured frames

Multi-light sections are turned on and off synchronously with the camera frame capture. Each section is turned on for several milliseconds and the camera exposure time is equal to the burning time of section. A very short burning time makes a multi-light system flicker-free, so that users can observe the sample with a naked eye or through eyepieces like under conventional lighting. The camera can´t capture every sequent section switching, because its frame capture speed is limited. For example, for a 80fps camera we can´t capture the next frame earlier than 12.5ms after the previous capture. That is why, the camera misses several sections switching. After the frame was captured for a concrete lighting section, a high-quality RAW image processing is done on PC by a GPU. When frames from all lighting sections are processed, they are merged together in one multi-light frame on the same PC. On figure 3 you see the scheme of multi-light image capture and processing for a configuration using a 5MP camera with maximum 80fps in RAW16 frame format, four section multi-light, and GTX 2080 Ti video card. For such a configuration we can get 20 multi-light 5MP frames per second, and the latency of a pipeline is 115ms. A multi-light processing pipeline can be tuned for cases when the lighting section power is not enough. Then several RAW frames with the same lighting can be captured and summed together giving a RAW frame with increased exposure, at the same time the system remains to be flicker-free. The multi-light technology can be easily added as an upgrade to current vision hardware. The lighting is changed to a multi-light one (with a synchronizing controller). For a real-time multi-light system the camera is changed with a high-speed camera, and the PC GPU should be upgraded too.

– For curved specular or transparent object inspections

the multi-light technology gives the best result, removing

highlights and enhancing the details.

– The technology works in real-time (up to 20fps for 5MP resolution).

The speed is actually limited by the speed of current high-speed camras.

– The illumination is flicker-free, so it is possible

for the operator looking at the sample with a naked eye.

– The complexity of a multi-light upgrade is

nearly the same as for a conventional lighting.

– You can switch between multi-light and

standard mode of illumination by one click.

– No light adjustment expertise or special

knowledge is required from the operator.