Material Options

When choosing a protective window, we first need to select the substrate material. For applications where the optics may be prone to scratches or used as a wear plate, a scratch resistant material should be selected. If the window will be exposed to high temperatures, like in a hot steel or glass factory, a material with a higher temperature rating is important. If the system uses a thermal or LWIR sensor, a material that can withstand harsh environments should be chosen. Let’s take a closer look at the available materials:

- Acrylic: Abrasion-, breakage- and solvent-resistant; durable, economical and laser-able; optical-grade and anti-reflection coated; oleophobic coating available.

- Fused Silica/Quartz: Ultra-low thermal expansion; withstands temperatures of up to 1,100°C; superior transmission in the UV; multi-layer anti-reflection coating available.

- Borofloat: Impact-, chemical- and alkali-resistant; withstands temperatures of up to 450°C, wavelengths range from UV, visible (VIS) and NIR; durable multi-layer anti-reflection coating; oleophobic coating available.

- Precision Windows: Made with precision polished N-BK7; low image distortion and stain-resistant; free of bubbles and inclusions; ideal for low power laser applications; excellent transmission in the VIS and NIR.

- Sapphire: Stronger than standard glass windows; durable to withstand harsh environments; impact-, chemical- and alkali-resistant; transmits wavelengths ranging from UV, VIS and SWIR.

- Germanium: Diamond-like carbon (DLC) coating; can withstand harsh environments; ideal for thermal camera enclosures; 7.5 to 12.5 micron useful range.

Optical Coating Options

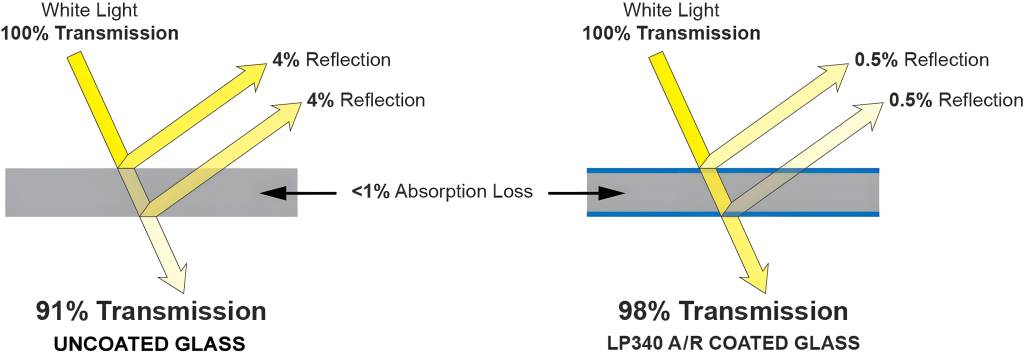

Coatings play an important role in how the protective window interacts with the vision system and environment. Choosing the correct coating combination is key to both optical performance and maintenance. Anti-reflection (AR) coatings can have direct impacts on light transmission of an optical window and clarity. By decreasing the amount of light reflecting off the surface, a higher percentage of light will pass through the protective window.

Without an AR coating, reflected light can create glare or hot spots on the window, which can lead to a loss of clarity – especially when used in front of a vision sensor. But when it comes to AR coatings, it’s not always one size fits all. Different AR coatings provide optimal transmission in the intended wavelength spectrum. For substrates that can be used in both the VIS and NIR range, Broadband Anti-Reflection (BBAR) coating is recommended. BBAR coating has a larger optical working range compared to standard AR coating while still providing all the AR benefits.

For protective and maintenance coatings, MidOpt offers a variety of solutions. Options like hard coating can provide the benefits of high scratch resistance and durability. This is commonly used to not only protect the window itself, but also protect other coatings such as AR and interference coatings. This will provide overall improved durability and longevity of the optics. For maintenance, an oleophobic coating resists moisture, oils, grease and smudging from fingerprints. This can prevent buildup of substances that could interfere with the clarity of the window.

Additional Lens Protection

Machine vision lenses can be fragile. Made up of a series of optical components, they help focus light onto the eye of a machine vision camera, the sensor. Many optical lenses are designed based on function and affordability rather than convenience, like adding a flat surface for easier cleaning. For this reason, many lens manufacturers include a filter thread on the front of the lens. While this filter thread is typically used for a machine vision filter, for applications where a filter isn’t in use, MidOpt can utilize this filter thread for a protective window. If it is in use, all MidOpt filters and protective windows have male and female threads for easy stackability. For additional lens protection, there is the LE110 Lens Enclosure. It not only protects the front of the lens, but also the entire body of the lens from dust and impact. The LE100 also prevents tampering. Once installed, settings put in place by a technician it cannot be inadvertently changed, making this an easy, low-cost insurance for the lens and vision system.