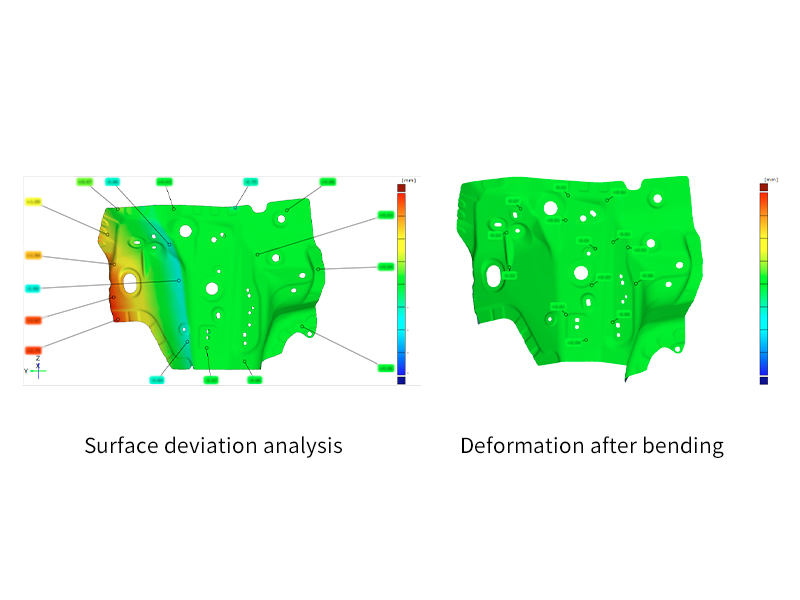

The automated 3D inspection solution AutoScan-T of Scantech allow users to inspect and analyze surface deviation, hole diameter, hole position, hole-to-hole distance, boundary, and gauge of stamping parts. With 17 blue laser crosses and optical tracking technology the system performs 3D scanning at a rate of up to 1.9 million MPS with an accuracy of up to 0.025 mm. The accuracy is not affected by external factors including robotic arms and guide rails. AutoScan-T can be located near the stand of a stamping press and enables customers to scan metal sheets in an average of three minutes and only one minute for small-size objects. The measurement system generates inspection reports in the form of a color map in real time.