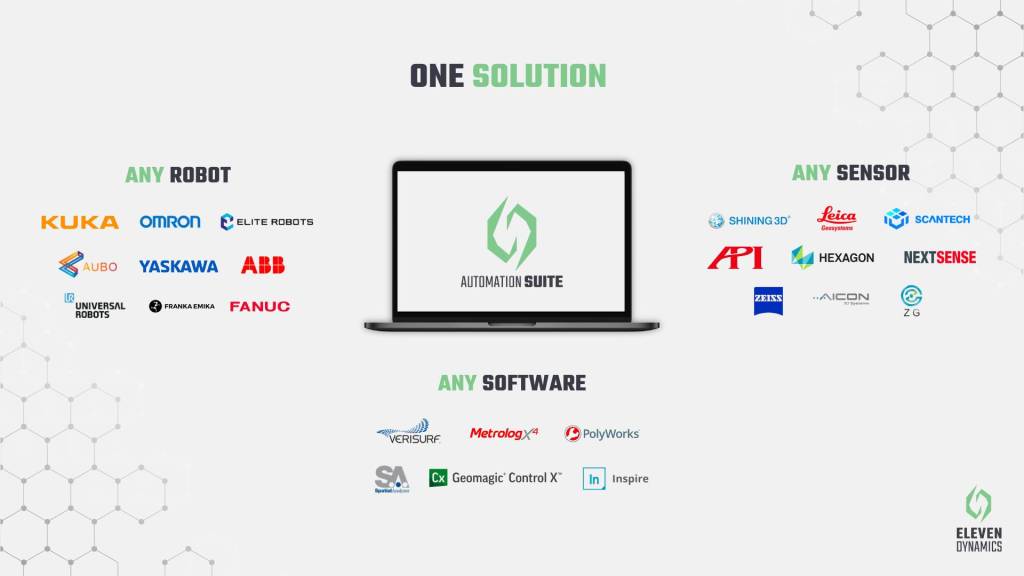

Eleven Dynamics introduces the software Automation Suite, an advanced open platform poised to redefine industrial automation. This next-generation solution seamlessly integrates diverse technologies into a single, efficient system, offering unmatched compatibility and flexibility.

Rubrik: Systeme & Lösungen

Camera Tomography

The heart of Tenta Vision’s new NDT systems is a patented sensor, essentially a camera that can look inside materials. This revolutionary technology, which is called ‚camera tomography‘, allows to identify both external and internal defects like voids, delamination, foreign materials, cracks, and more in mere seconds. The technology is material-independent and can penetrate up to 30mm beneath the surface of softer materials.

NDT for Composites

Previously, active thermography has often been used as a qualitative method, providing a quick, non-contact overview of the integrity of a component. In the event of any thermal anomalies, a second test method, in most cases ultrasonic, had to be used to determine absolute defect sizes. Photothermal tomography with the compact 3D V-ROX by Voidsy enables 3D defect visualization and an easy automation of inspection tasks. It significantly increases the efficiency of determining the lateral defect size and the defect depth.

AR for Industrial Quality Control

Avoiding production failures and preventing costly downtimes and rework are crucial in manufacturing. Twyn is Visometry’s mobile Augmented Reality (AR) software platform that empowers organizations to create inspection plans and conduct real-time quality inspections using tablets right on-site, wherever parts are manufactured or stored.

Smart 3D Vision for Robots

Roboception has recently introduced a 3D stereo vision platform that is based on the Nvidia Jetson Orin and features leading-edge resolution and accuracy. It runs the provider’s own software as well as any additional software elements all within a compact device. In addition, the company has developed a new approach to providing the robotic systems with ‚visual abilities‘.

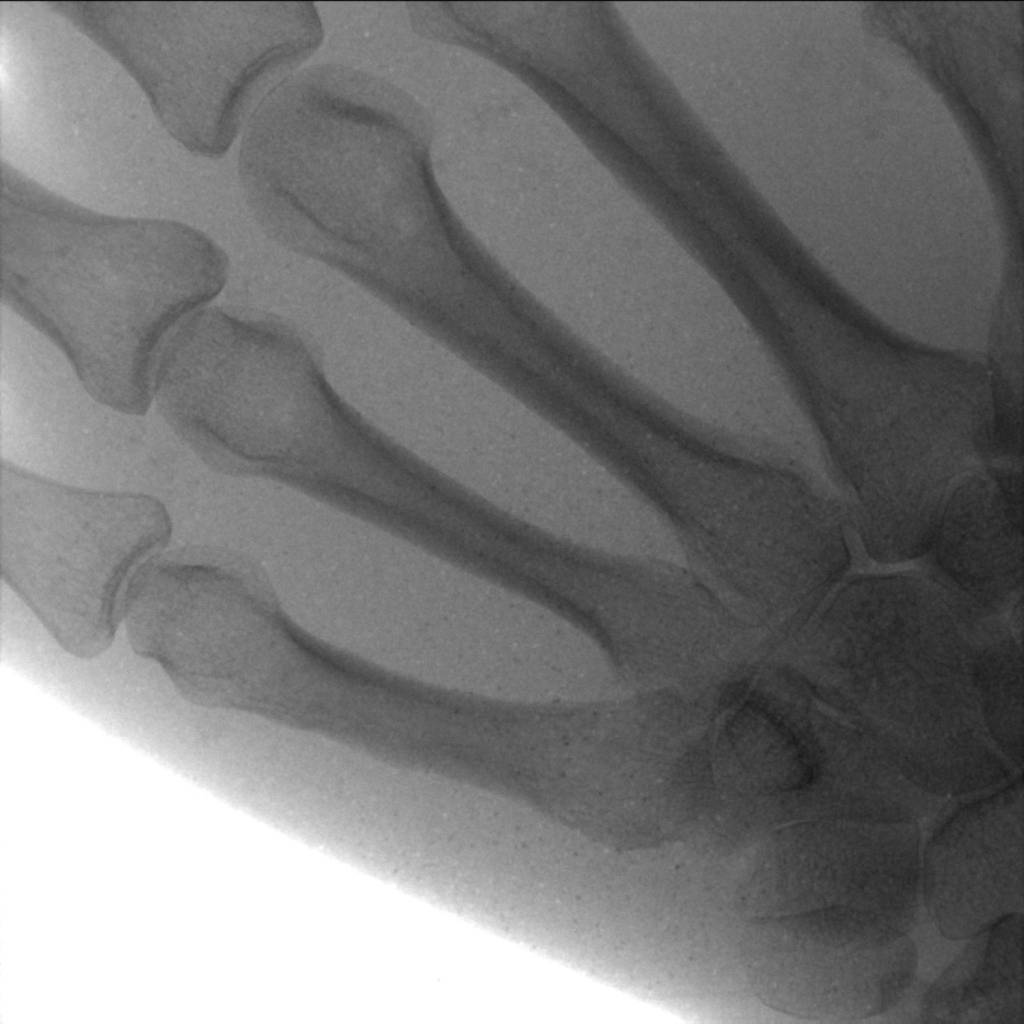

From X-Ray to SWIR

QDI Systems, a Dutch company, has developed a new technology based on colloidal quantum dots (QDs), poised to revolutionize the image sensors industry. Currently, the quantum dots material being produced serves as a platform technology, with a focus on three key application areas: direct and indirect conversion X-ray sensors, as well as short-wave infrared (SWIR) sensors.

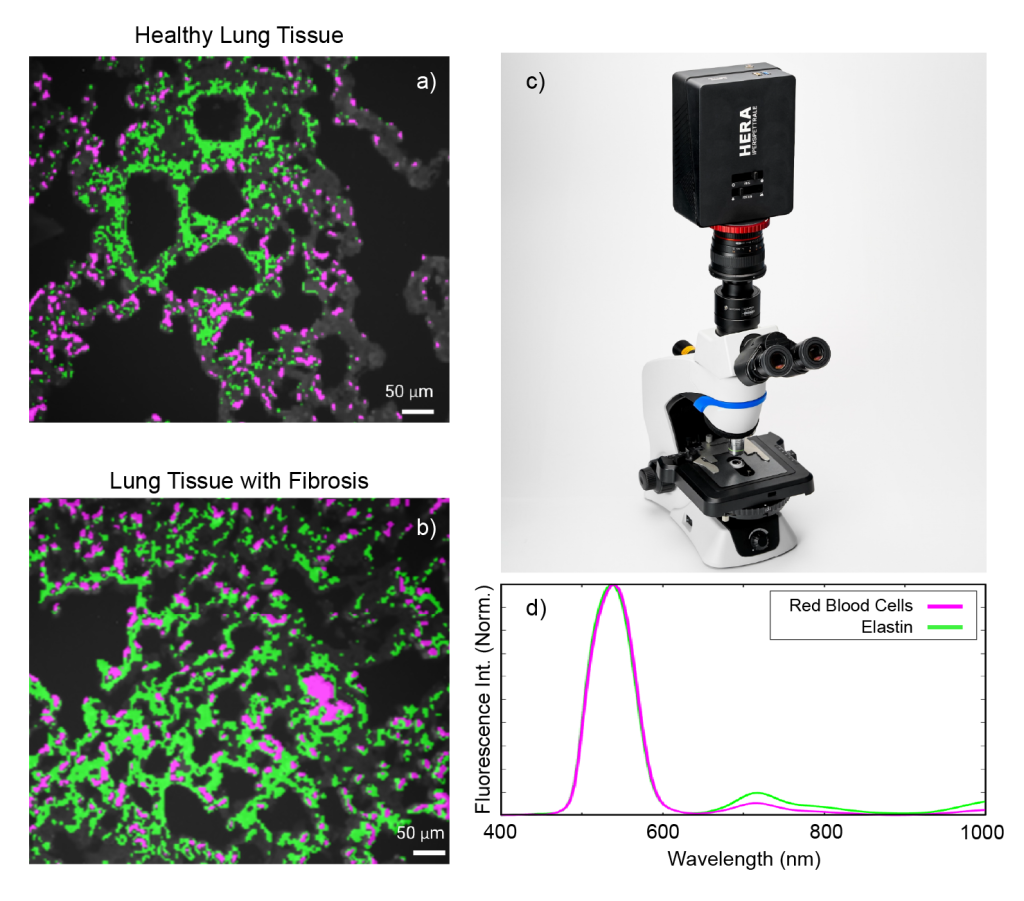

Ultraspectral Imaging

From remote sensing to microscopy, the novel Hera camera of Nireos is an easy-to-use, point&shoot hyperspectral camera, ideal to characterize samples in the lab or monitor the quality of products without any compromise on data quality and resolution.

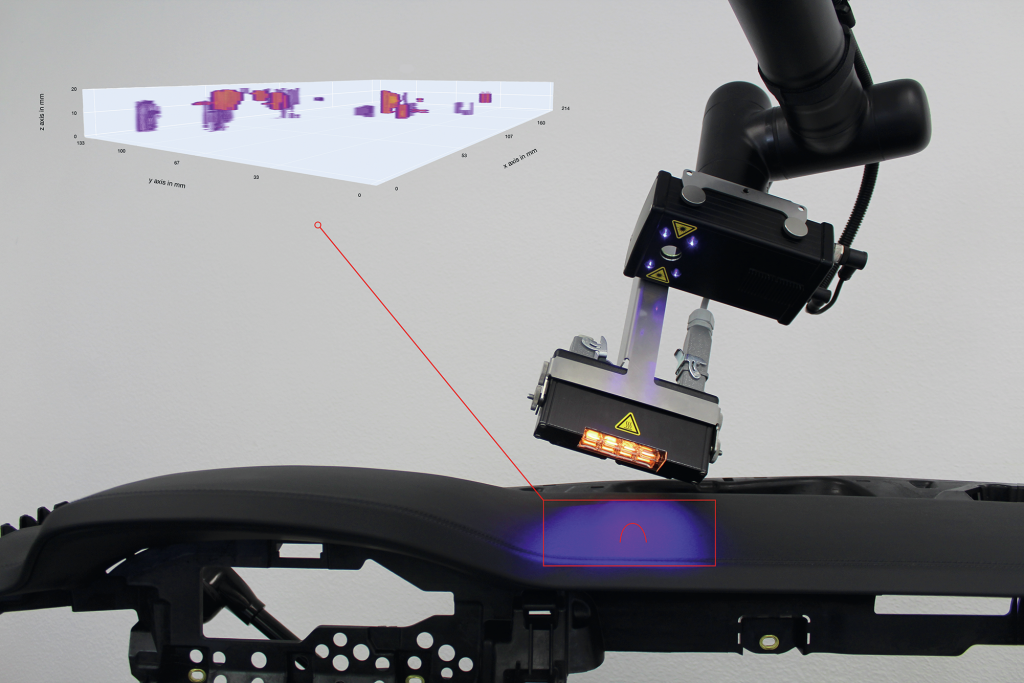

Weld Seam Inspection

Iuna AI Systems specializes in the development of deep learning-based image processing software and camera systems. Since its founding in 2020 the company has aimed to automate quality assurance in industrial manufacturing using AI technology. In this article, the benefits and applications of the AI Weld Seam Vision System for quality assurance of MIG/MAG weld seams and other possibilities for automation through AI-based computer vision are highlighted.

Tagless Traceability

Labeling is the most widely used method for tracing components. Thanks to a new technology from Detagto, labels are no longer necessary. Instead, surface patterns of components are used as a ‚fingerprint‘ to distinguish even individual series parts produced under identical conditions. These unique structures are due to random, stochastic processes and are often not visible to the naked eye.

Startup Ecosystem

Startups represent innovation and often drive significant technological advancements. They develop new, often disruptive technologies and bring them to market quickly. 2018 marked a peak in developments in artificial intelligence (AI) in the B2B sector. This was evident as many startups, as well as universities and research institutes, were gearing up and actively seeking collaboration and exchange with companies and investors.